Open Molds

- HLU Molds in Polyester, vinyl ester or epoxy resins.

- Molds for both side finish parts, hollow parts.

- Typical Applications- HLU molding, vacuum bag molding, infusion, cutting templates, low volume vacuum forming molds, etc.

- TURNKEY programs with patterns, molds, startup and manufacturing support.

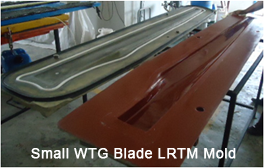

LRTM Molds

- Molds in vinyl ester or epoxy resins.

- Thick, reinforced, lower mold.

- Upper mold in flexible silicone or Semi-rigid composite material.

- Typical Applications- Automotive, industrial, medical, in-situ foam molded small wind blades, etc.

RTM Molds

- Machine metal or Steel reinforced composite molds

- Integrated thermal regulation systems, vacuum systems.

- Typical Applications- Automotive, industrial, medical.

Molds for RIM/DCPD/LFI

- Cast / machined aluminum

- Reinforced composite mold for low volume.

- Integrated heating / cooling systems.

- Typical Applications- Transportation, Automotive, industrial.

Carbon Fiber Molds

- Carbon fiber molds for long mold life and better efficiency.

- Integrally heated, vacuum systems.

- Integrated heating / cooling systems.

- Typical Applications- Out of Autoclave, autoclave molding, infused epoxy and carbon/kevlar fiber cured in oven, Wind Turbine Blade molds, etc.

Other Features:

- Molds with scribe lines and with detailed trimming considerations.

- Final machining of composite molds for higher precision (+/- 50 microns).

- High temperature molds – upto 160 °C use.

- Mold inspection reports using laser and/or white/red light scanning vacuum integrity tests.

- Trial and startup support.

Other Features:

- Molds with scribe lines and with detailed trimming considerations.

- Final machining of composite molds for higher precision (+/- 50 microns).

- High temperature molds – upto 160 °C use.

- Mold inspection reports using laser and/or white/red light scanning vacuum integrity tests.