Case Study - Wind Energy

- In House Facility for structural laminate design, pattern design, various molds, jigs and fixtures.

- Patterns CNC machined and finished to high gloss in MDF and Epoxy paste on EPS foam.

- Up to 3 molds from the same pattern.

- Small WTG molds in Vinyl ester or Post cured Epoxy molds.

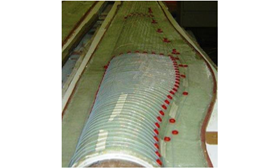

- Moulds with integrated heating and vacuum system.

- Life 1000 to 1200 blades.

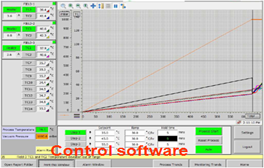

- In house developed automated heating and vacuum system.

- Mold Manufactured by infusion for light weight and strong molds.